Companies learned during the pandemic that a strong supply chain isn’t one sheltered from disruption but one that is resilient in the face of it.

While COVID-19 is arguably one of the most significant disruptions to impact global supply chains; supply chain shocks and disruptions occur fairly frequently. These disruptions may vary based on their severity or frequency across a range of areas such as economic, regulatory, geopolitical, trade issues, natural disasters, supply shortages and quality issues; but these supply chain shocks occur with a lot of regularity.

COVID-19 was a catalyst for many companies to assess their supply chain resiliency; with 93% of executives planning to make their supply chains more resilient according to a recent study from McKinsey1. Companies in the pursuit of supply chain resiliency will need to place greater emphasis on digital supply chain planning technology to help them mitigate risk, reduce uncertainty, gain agility, and tackle disruptions.

The Role of Digital Supply Chain Planning Technology

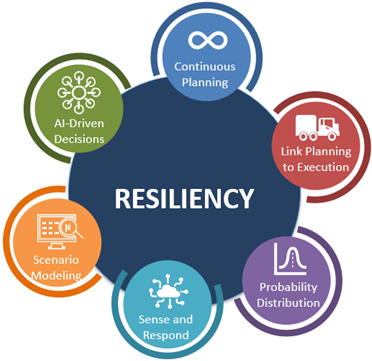

Working with hundreds of companies, John Galt Solutions has identified 6 key capabilities that are critical to enable resiliency.

1. Continuous Planning:

Companies need now more than ever a digital supply chain planning platform that delivers a continuous planning environment. This continuous planning environment automatically integrates internal and external data sources into the planning environment and seamlessly synchronizes multiple planning horizons (hourly, daily, weekly, monthly, quarterly, annual, etc) in real-time. A unified data model provides the underlying architecture and strong foundation to support a continuous planning environment. John Galt’s Atlas Planning Platform is precisely designed to enable a continuous planning environment.

2. Linking Execution to Planning:

To manage risk and gain visibility into the supply chain, companies will need to incorporate short term planning signals (those traditionally found in the execution layer such as transportation, IoT, external data sources, etc.) to refine longer range plans. While traditionally companies separated planning and execution functions, these areas are very slowly starting to converge. A digital supply chain planning platform helps companies break down traditional siloes by connecting to the real-world bidirectionally across diverse applications such as transportation systems and be able to continuously model changes to the plan taking into account changes in lead time, port disruptions, and beyond. Linking these short-term planning signals further drives end-to-end supply chain visibility.

3. Probability Distribution:

The real world that companies operate is volatile and uncertain - be it supply chain shocks, demand variation, supplier performance, etc. Companies need to shift from asking “How accurate are our plans?” and instead take into account variability and uncertainty into the plan. Doing so will require companies to leverage supply chain planning technology that helps create a range of plans that improve the relevant probability function and determine which plans are most resilient to variability.

4. Sense and Respond:

To cope with variability, companies need to tap into external data signals such as POS (point of sale), IoT, weather, distributor data, etc. to be able to detect demand and supply changes. Incorporating these data signals improves demand sensing, demand shaping and forecasting in the short-term horizon to help prioritize product deployment and react faster to specific market conditions.

5. Scenario Modeling:

Having the ability to model and simulate the impact of a change in the supply chain is critical. Companies can run hundreds of scenarios and simulate virtually anything – supply changes, demand changes, capacity changes, and more. Being able to test and evaluate a range of possibilities gives confidence to executives and their supply chain teams knowing that that each scenario created represents the optimal plan for a specific combination of trigger events. “What-if” scenarios give companies the ability to view, compare, collaborate, and assess the assumptions, risks, and outcomes across the supply chain.

6. AI Driven Decisions:

In today’s dynamic market landscape, there are hundreds of factors that can potentially impact the supply chain. Artificial intelligence and machine learning automate the system’s ability to combine and analyze immense data streams and identify complex patterns. Artificial intelligence and machine learning help manage complexity, automate plans, and assist planners in making better decisions by providing new insights into the supply chain.

Having a resilient supply chain will enable a company to:

- Become more agile and flexible

- Reduce uncertainty and mitigate risk

- Improve the quality of the supply chain planning decisions

Companies seeking to become more resilient need to have capabilities across these six key areas. Embrace concepts such as probability distribution that are a stark contrast to more traditional planning concepts focused on accuracy. Click here to learn more about Atlas Planning Platform, and how John Galt Solutions is helping hundreds of global customers become more resilient.

1 McKinsey survey of global supply chain leaders, May 2020